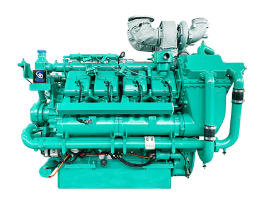

Diesel Engine

Generator Set

Compared to traditional diesel engines, electronic fuel injection diesel engines have significant improvements in exhaust emissions.

In terms of nitrogen oxide (NOx) emissions, traditional diesel engines are prone to producing large amounts of NOx in high-temperature and oxygen rich areas during combustion due to inaccurate fuel injection. The electronic fuel injection diesel engine can precisely control the timing, pressure, and injection quantity of fuel injection through a precise electronic control unit (ECU). It can adjust the fuel injection strategy in real-time based on the engine speed, load, and other operating conditions. For example, under high load conditions, delaying the injection time reasonably and reducing the combustion temperature can effectively reduce the generation of NOx. Through this precise control, the NOx emissions of electronic fuel injection diesel engines can be reduced by about 30% -50% compared to traditional diesel engines.

For particulate matter (PM) emissions, the traditional mechanical fuel injection method of diesel engines can easily lead to poor fuel atomization, resulting in incomplete combustion of the fuel and the generation of a large number of soot particles. The electronic fuel injection diesel engine adopts advanced fuel injectors, which can make the fuel atomize more finely and evenly. After the fuel particles become smaller, the contact area with the air increases, resulting in more complete combustion. This greatly reduces the emission of incompletely burned carbon particles, allowing for a reduction of approximately 40% -60% in PM emissions.

In terms of carbon monoxide (CO) and hydrocarbon (HC) emissions, electronic fuel injection diesel engines also perform well. Traditional diesel engines produce more CO and HC due to insufficient combustion. The electronic fuel injection system can accurately control the fuel injection amount based on the intake volume, ensuring the optimal mixing ratio of fuel and air, and making the combustion process closer to the ideal state. In this way, the emissions of CO and HC will also be significantly reduced, generally by about 30% to 70%.

In addition, electronic fuel injection diesel engines can also be equipped with exhaust aftertreatment systems, such as selective catalytic reduction (SCR) devices and particulate filters (DPF). SCR devices can convert NOx in exhaust gas into harmless nitrogen and water, while DPF can effectively capture and oxidize particulate matter, further reducing harmful exhaust emissions and enabling the exhaust emissions of electronic fuel injection diesel engines to meet increasingly stringent environmental regulations. This series of improvement measures have made electronic fuel injection diesel engines play an increasingly important role in environmental protection and sustainable development.