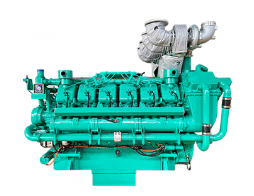

Diesel Engine

Generator Set

A four stroke engine includes an intake stroke, a compression stroke, a power stroke, and an exhaust stroke. The specific working process of each stroke is as follows:

Intake stroke

At the beginning of the intake stroke, the piston is located at top dead center. At this point, the intake valve opens and the exhaust valve closes. As the piston moves downwards, the pressure inside the cylinder decreases, forming negative pressure. Under the pressure difference, a mixture of air and fuel (for gasoline engines) or pure air (for diesel engines) is drawn into the cylinder. When the piston reaches the bottom dead center, the intake stroke ends and the cylinder is filled with a mixture of gas or air.

compression stroke

After the intake stroke, both the intake and exhaust valves are closed. The piston moves upward from the bottom dead center, compressing the mixture (or air) inside the cylinder. During this process, the temperature and pressure of the mixture (or air) continuously increase. Compression ratio is an important indicator for measuring the degree of compression, which has a significant impact on the performance and efficiency of the engine. When the piston reaches the top dead center, the compression stroke ends, and the mixture (or air) is in a high temperature and high pressure state.

power stroke

At the end of the compression stroke, for gasoline engines, spark plug ignition ignites the mixture for combustion; For diesel engines, the fuel injector injects diesel into the high-temperature and high-pressure air, and the diesel burns on its own. The high-temperature and high-pressure gas generated by combustion rapidly expands, pushing the piston downward. This process is the key link in converting the chemical energy of fuel into mechanical energy. The piston drives the crankshaft to rotate through the connecting rod, outputting power outward. When the piston reaches the bottom dead center, the power stroke ends.

Exhaust stroke

After the power stroke is completed, the exhaust valve opens while the intake valve remains closed. The piston moves upward from the bottom dead center, expelling the burned exhaust gas from the cylinder. When the piston reaches the top dead center again, the exhaust stroke ends, and a working cycle is completed. Then, a new intake stroke begins, and this cycle repeats itself.

The key to their collaborative continuous operation lies in the rotation of the crankshaft. The crankshaft obtains power rotation during the power stroke and drives the piston to complete the other three strokes through the connecting rod. The close coordination between each stroke is carried out in the order of intake compression work exhaust, and the opening and closing of valves are controlled at appropriate times to ensure the continuous and stable operation of the engine. At the same time, the valve train and timing system of the engine ensure precise coordination between valve opening and closing time and piston movement, allowing each stroke to occur at the correct time, thereby achieving efficient and stable energy conversion and power output.