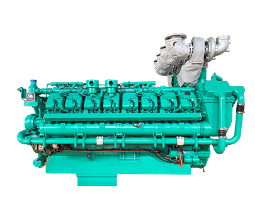

Diesel Engine

Generator Set

The fuel consumption rate of diesel generators is an important performance indicator, which is influenced by various factors.

1、 Load size

Load size is one of the key factors affecting fuel consumption rate. When the diesel generator is in full load operation, the engine needs to output a large amount of power to meet the load demand. At this point, the fuel consumption rate is relatively high. Because the engine needs to overcome greater resistance to do work, it needs to burn more diesel to provide sufficient energy. For example, a 50kW diesel generator has a lower fuel consumption rate when unloaded, but when it operates with a load of 40kW-50kW, the fuel consumption rate will significantly increase.

2、 Engine performance

Efficiency of the engine

The efficiency of engines produced by different models and manufacturers varies. Efficient engines can burn diesel more efficiently, converting chemical energy into mechanical energy more effectively, thereby reducing fuel consumption. For example, engines that use advanced combustion technology and optimized intake and exhaust systems have more complete fuel combustion. Compared to traditional technology engines, the fuel consumption rate may be reduced by 10% -20% at the same power output.

Power configuration of engine

If the engine power configuration of the diesel generator is too high and there is a large margin relative to the actual load, the engine may not work in the optimal efficiency range during operation, resulting in an increase in fuel consumption rate.

3、 Operating environment

temperature

The ambient temperature has a significant impact on fuel consumption rate. In low-temperature environments, the viscosity of diesel increases, the atomization effect deteriorates, and combustion is insufficient. In order to ensure the normal operation of the engine, measures such as preheating the diesel need to be taken, and the engine also needs to consume more energy to overcome the adverse effects of low temperature, thereby increasing the fuel consumption rate. On the contrary, in high-temperature environments, although diesel atomization is better, the engine cooling system requires more energy to maintain normal operating temperature, which will also affect the fuel consumption rate to some extent.

Altitude

As the altitude increases, the air density decreases. This will result in a decrease in the amount of air entering the engine cylinder, causing a change in the mixing ratio of diesel and air, and affecting the combustion process. In order to maintain power output, the engine needs to inject more diesel, which leads to an increase in fuel consumption rate.

4、 Maintenance and upkeep status

Air filter

If the air filter is clogged and the amount of air entering the engine is insufficient, it will cause an imbalance in the mixing ratio of fuel and air, resulting in insufficient fuel combustion and an increase in fuel consumption rate.

Fuel injector

Malfunctions in the fuel injector, such as uneven fuel injection and inaccurate injection pressure, can affect the injection efficiency of diesel fuel, resulting in incomplete combustion of fuel in the cylinder and increasing fuel consumption rate. Regular inspection and maintenance of fuel injectors can ensure their normal operation and help reduce fuel consumption.