- Home

- Products

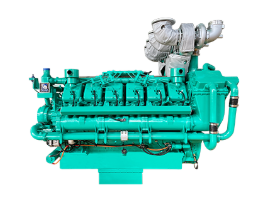

DIESEL ENGINE

GENERATOR SETS

- Power Solution

- Service Support

- About Us

- Blog

- Contact

DIESEL ENGINE

GENERATOR SETS

There are many differences between gas engines and fuel engines in terms of intake and exhaust systems.

1、 Air intake system

Intake composition

The main intake of a fuel engine is air, which enters the cylinder through the intake duct and provides sufficient oxygen for the combustion of fuel. For example, in a gasoline engine, air and gasoline are mixed in a certain ratio (theoretical air-fuel ratio of approximately 14.7:1) before entering the combustion chamber.

The intake of a gas engine is mainly a mixture of gas and air. Taking natural gas engines as an example, the main component of natural gas is methane, which is mixed with air in appropriate proportions. Due to the different physical and chemical properties of gas compared to fuel, its mixing ratio also varies. The air-fuel ratio range of a typical natural gas engine is between 15.5-18:1.

Air intake method

There are various intake methods for fuel engines. The traditional carburetor engine atomizes fuel through a carburetor and mixes it with air before entering the cylinder; Modern fuel injection engines, on the other hand, precisely control the fuel injectors through an electronic control unit (ECU) to inject fuel into the intake duct or cylinder and mix it with air.

Gas engines typically use intake injection to inject gas into the intake and mix it with air. This is because the state of gas itself (such as natural gas being gaseous) is relatively easy to mix evenly with air in the intake duct, and this method is conducive to precise control of the mixing ratio of gas and air, improving combustion efficiency.

Differences in intake system components

The intake system of a fuel engine mainly includes an air filter, intake duct, throttle valve (for electronically controlled fuel injection engines), etc. The air filter is used to filter impurities in the air, while the throttle valve controls the intake volume.

In addition to air filters and intake pipes, the intake system of a gas engine also requires a specialized gas supply device, such as a gas pressure regulator. The gas pressure regulator is used to adjust the gas pressure to a suitable range to ensure that the gas can be stably injected into the intake duct and mixed with air.

2、 Exhaust system

Differences in exhaust composition

The main components in the exhaust of fuel engines are carbon dioxide, water vapor, carbon monoxide, hydrocarbons, and nitrogen oxides. Among them, carbon monoxide, hydrocarbons, and nitrogen oxides are the main pollutants.

The carbon dioxide content in the exhaust composition of gas engines does not change significantly compared to fuel engines, but the emissions of carbon monoxide and hydrocarbons are significantly reduced. This is because gas combustion is relatively sufficient and produces relatively fewer harmful pollutants.

Differences in requirements for exhaust system components

The exhaust system of a fuel engine requires the installation of devices such as a three-way catalytic converter to purify the exhaust gas, converting carbon monoxide, hydrocarbons, and nitrogen oxides into harmless carbon dioxide, water vapor, and nitrogen.

Due to the relatively low pollutant content in the exhaust, gas engines have less stringent requirements for exhaust purification devices, but may also require some simple oxidation catalysts to further reduce small amounts of carbon monoxide and hydrocarbon emissions. At the same time, the material of the exhaust system of gas engines needs to adapt to the characteristics of gas combustion products in terms of corrosion resistance. For example, the sulfur content in the exhaust of natural gas engines is low, but their exhaust temperature may be high, which requires exhaust system materials to have good high-temperature resistance.