- HOME

- ABOUT GOOGOL

- PRODUCTS

DIESEL ENGINE

GENERATOR SETS

- DOWNLOAD

- CASES

- NEWS

- CONTACT US

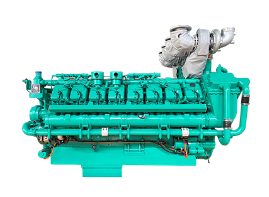

DIESEL ENGINE

GENERATOR SETS

In electronic fuel injection diesel engines, sensors play a crucial role, just like the sensory organs of the human body, providing key information for precise control of the engine.

Firstly, the intake pressure and temperature sensors are important components. The intake pressure sensor can monitor the air pressure entering the cylinder. It detects the intake pressure and allows the electronic control unit (ECU) to accurately calculate the intake volume. Because air quantity is one of the key factors determining fuel injection quantity, only by accurately understanding the intake air quantity can fuel and air be mixed in the optimal ratio, thereby achieving complete combustion. The intake temperature sensor is responsible for monitoring the intake temperature. The change in intake temperature will affect the air density, which in turn affects the intake volume. For example, in cold weather, the intake temperature is lower, the air density is higher, and the oxygen content in the same volume of intake is higher. The ECU will adjust the fuel injection quantity and timing appropriately based on the feedback from the intake temperature sensor, ensuring that the engine can operate stably and efficiently at various ambient temperatures.

The crankshaft position sensor and camshaft position sensor are also indispensable. The crankshaft position sensor can accurately detect the position and speed of the crankshaft. It provides information on engine speed to the ECU and determines the piston position of each cylinder through the position of the crankshaft, allowing the ECU to accurately control the injection timing and sequence. The camshaft position sensor is mainly used to determine the opening and closing timing of the valves. It works in conjunction with the crankshaft position sensor to ensure accurate valve timing and fuel injection timing of the engine. This is crucial for the normal operation and power output of the engine, like a precise conductor directing the various components of the engine to work at the correct pace.

In addition, there is a fuel pressure sensor. It monitors the fuel pressure in the fuel system, and when there are abnormal fluctuations in pressure, the ECU can respond promptly. If the fuel pressure is too low, it may lead to insufficient fuel injection, affecting the engine's power performance; Excessive fuel pressure may damage components such as fuel injectors. The fuel pressure sensor can ensure that the fuel pressure is within the appropriate range, enabling the fuel injection system to operate normally.

In short, sensors in electronic fuel injection diesel engines monitor various working parameters in real time and feed back this information to the ECU, enabling the ECU to accurately control the engine's fuel injection, valve timing, and other operations, thereby ensuring stable, efficient engine performance and emission compliance.