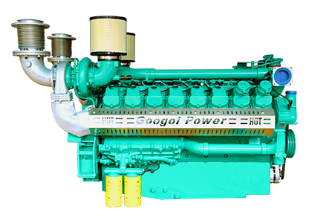

Diesel Engine

Generator Set

The fuel injection system of an electronic fuel injection diesel engine is mainly controlled by an electronic control unit (ECU) to accurately control the timing, pressure, and quantity of fuel injection, in order to achieve efficient combustion.

The working process starts with sensors. Multiple sensors play a crucial role in electronic fuel injection diesel engines. For example, a crankshaft position sensor can accurately detect the angle and speed of the crankshaft. It transmits this information to the ECU, which is like providing the "heartbeat" data of the engine to the ECU, because the engine speed and crankshaft position are crucial for determining the timing of fuel injection. There are also intake pressure and temperature sensors that can sense the amount and temperature of air entering the cylinder. The amount of air directly affects the calculation of fuel injection, as fuel and air need to be mixed in a certain proportion to achieve optimal combustion efficiency.

When the ECU receives information from these sensors, it will process it according to pre-set programs and algorithms. Like a shrewd commander, the ECU integrates all data to calculate the optimal fuel injection quantity, injection time, and injection pressure.

When performing fuel injection actions, it is mainly accomplished through fuel injectors. The injector is a key component of the fuel injection system, connecting the fuel pipeline and cylinder. When the ECU issues an injection command, the solenoid valve inside the injector will quickly open. At this time, the high-pressure fuel provided by the high-pressure fuel pump will be sprayed into the cylinder in a mist through the injection holes of the injector. This misty fuel can be fully mixed with air, providing good conditions for combustion. Moreover, the electronic fuel injection system can achieve multiple injections, such as pre injection, main injection, and post injection under certain operating conditions. Pre injection can reduce combustion noise and nitrogen oxide emissions, while main injection provides the main power fuel, and post injection can further clean the combustion chamber and reduce particulate matter emissions.

Throughout the entire working process, the fuel injection system will continuously adjust according to the real-time operating conditions of the engine. For example, when the engine load suddenly increases, the sensor will immediately sense the change and transmit the information to the ECU. The ECU will accordingly increase the fuel injection amount and adjust the injection time to ensure that the engine can output power smoothly, while ensuring efficient use of fuel and lower emissions.